All our services

Materials Characterization

- Choosing adhesives for multi-material assemblies- Residual stress determination

- Retained austenite quantification by energy dispersive X-ray diffraction (EDXRD)

- Mechanical properties of metallic materials

- Chemical analysis and composition of metallic materials

- Metallographic examinations of metallic materials

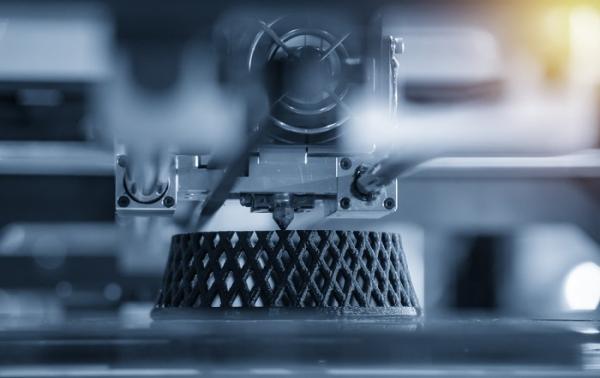

- Additive manufacturing: characterising materials

- Characterization of materials in fatigue

- Metal powder characterization

- Testing and analysing polymer/composite materials

- Support for selecting materials for pressure equipment

- Support for machine material selection

- Selection of gear wheels materials and treatments

- Tools and tool coatings characterization and adjustment

- Selection of materials/process pairs

Surfaces and treatments

- Engineering of painting systems (products and processes)- Simulation of treatment processes

- Innovative surface coatings : Sol-gel coating

- Expertise in surface treatment and surface coating

- Surface and heat treatment of metals

- Define and validate your surface finishing and texturing technologies

- The surface to improve performance

Design and simulation

- Noise and vibration design and adjustment- Leak-tight design

- Integration of composite materials in your products

- Scanning / Reconstructing your products in 3D

- Develop innovative and environmentally-responsible products

- digital engineering: calculation and simulation

- Reduce the environmental impact of your industrial activities

- Design of power transmission systems

- Study, design and manufacturing of mechatronic prototypes

- Design of industrial manufacturing ranges

- Process-product optimization

- Support to pressure equipment design

Industrial control, efficiency in production

- Additive Manufacturing: supporting you throughout the value chain- Development and integration of robotic solutions

- Innovative and differentiative production technologies

- Change your industrial organisation

- Deploy smart machining processes

Testing and Products reliability

- Qualify the earthquake behaviour of equipment- Supporting your test data management

- Qualification of dynamic seals

- Electromagnetic compatibility testing

- Environmental testing

- Test and characterisation of pressure accessories and equipment

- Test Engineering

- Design and validation of powertrains and peripherals for electric vehicles

- Part and composite structure manufacturing engineering

- Tests and characterisation of bonded assemblies

- Characterization of pressure equipment and accessories

- Control of composite specimen manufacturing

- Testing of sealing products and components

- Cetim: serving the biomedical industry

- Expertise of lubricants used in your industrial process

- Qualification of pumps and pumping equipment

- Optimization of pumping equipment and networks

Every mechanical skill with only one contact

The services offered by Cetim add to its research activity and collective projects.

By developing a multi-disciplinary approach combining all mechanical skills, Cetim offers its customers, SMI, corporations or experts something unique on the market.

Cetim's ability to answer major calls for tenders as well as individual needs, and its efforts to develop service and responsiveness set the organization as a unique actor and expert in mechanichal engineering at your disposal.