Back > Product and process engineering

Qualification of dynamic seals

Test benches to qualify and validate dynamic seals

The green energy transition imposes, inter alia, better control of friction (highly energy consumers) and leaks (pollution).

You are a manufacturer of dynamic seals, you want to improve, optimise or check the sealing performance of your seals:

- Validation of a new design, a new product or a leak-tightness level

- Performance of qualification or characterisation tests

- Control of wear, friction or durability

You are a user of dynamic seals and want to characterise, qualify or check the sealing performance of your seals:

- Determination of the possibility of integrating this type of seals into your equipment

- Performance of qualification or characterisation tests

- Performance of endurance tests, severisation tests, etc.

More generally, you want to determine the sealing performance of dynamic seals under specific operating conditions, in accordance with standards, etc.

We can provide assistance throughout your project:

- Development of specific tests under high speed conditions

- Support in the drafting of the test protocols as needed

- Performance of standardised tests or tests in accordance with particular specifications, either on a testing platform or at the customer’s site

- Correlation of experimental tests and numerical simulations

- Failure analysis of dynamic seals

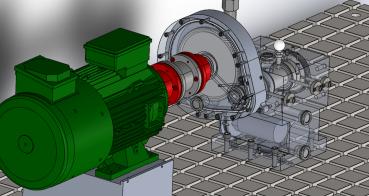

Our test benches are specific and unique in Europe:

- Temperature: -50 to 200°C

- Pressure: -1 to 50 bar

- Fluid: water, oil, gas, etc.

- Rotational speed: up to 25,000 rpm

Identification of possible answers and solutions regarding the green energy transition

A modular testing platform with unique testing facilities in Europe

Technicians, engineers and dedicated experts with multidisciplinary knowledge

Recognised expertise in dynamic sealing (joint laboratory with universities, and experience feedback on a wide range of dynamic seals)

We provide assistance to ensure the transition from a low TRL to industrial production

A specifically-compiled package of training courses from Cetim Academy® (classroom teaching and distance learning):

Confinement of refrigerants

Improve the confinement of refrigerants (CFC, HCFC gases) in your equipement and facilitiesExpertise in tightness failures analysis

Our full range of expertise to help you quickly and accurately identify the causes of leaksFailure of thermofluidic installations and equipment

All our expertise for reliable thermofluidic systemsTesting of sealing products and components

Characterise and qualify your sealing products and componentsLeak-tight design

Complete your design work with our sealing expertise

Testing and Products reliability

Qualifying, characterising in order to make sure that the product will fulfil the expected function, but also in order to optimise its performance or to implement quality control: the tests carried out by Cetim apply to all mechanical fields, from the most general to the most specialised one.

Cetim’s experts perform a customised service, from simple standard tests to the design of specific test benches.