About us

Cetim, the French technical center for mechanical industries is one of the largest industrial research organizations in Europe.Internationally recognized, its experts participate in major industrial challenges of today and tomorrow. Cetim is a reference in the world of innovation for an industrial future attentive to the planet.

Providing innovation to the mechanical industry for 50 years

Thanks to 50 years of experience, Cetim provides rare multidisciplinary competencies to succeed your project through high value support combining outsourced R&D, technological engineering, project engineering and consulting.slide 2 of 6

+

R&D Partnerships

Common laboratories

Seats in international standarization committees

+

Active clients worldwide

Scientific papers per year

Engineers and scientists

Our intervention areas

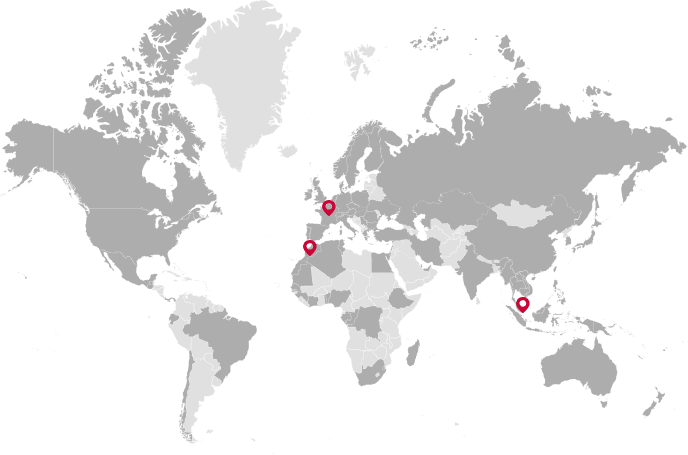

Together with our international subsidiaries and partners, we accelerate your environmental and digital transformation to success considering your local issues.

Europe

Cetim is today one of the European leaders in R&D and technology transfer.Middle East and Africa

Original partner of North Africa industrial actors with Cetim Morocco in Casablanca.Asia Pacific

Cetim deploys its expertises for over 30 years through Cetim Matcor located in Singapore.They trust us

News and Events

Read

Automotive

26/05/2025

SIA POWERTRAIN 2025

Meet Cetim at the SIA POWERTRAIN international conference, Booth N°17, June 11-12 in Le-Port-Marly, France.

Cetim, a leading player in R&D and technological engineering, is committed to supporting the automotive industry in its transition towards sustainable and decarbonized mobility.

At the SIA Powertrain 2025 conference, held on June 11–12 in Le Port-Marly, France, Cetim will showcase its comprehensive solutions and services aimed at enhancing competitiveness through electrif...

Read

Aerospace

26/05/2025

Cetim acquires an exceptional research equipment dedicated to liquid hydrogen

As part of “HyMEET”, its strategic hydrogen project” which aims to overcome technological barriers linked to production, transportation, storage and usage of hydrogen, Cetim has acquired a helium and hydrogen liquefier and the associated cryostats. The first tests will be carried out within the framework of European collaborative R&D projects dedicated to the aerospace sector, in which Cetim is involved.

Liquid hydrogen applications – and the associated field of deep cryogeni...

Read

Aerospace

21/05/2025

When Cetim trains future hydrogen specialists…

Two experts of the Centre have been invited to take part at the new “HyDEN” master's program at the IFP school.

The IFP School, an engineering school recruiting mainly students with five years of higher education and specializing in energy, transport and environment, offers an Advanced-Master program (Mastère spécialisé®) "Hydrogen Project and Engineering" which provides a global perspective on the hydrogen industry in France and abroad.

"This new program embodies IFP Scho...

slide 2 of 3

Engage with an expert