Mecatheque

Results of collective works

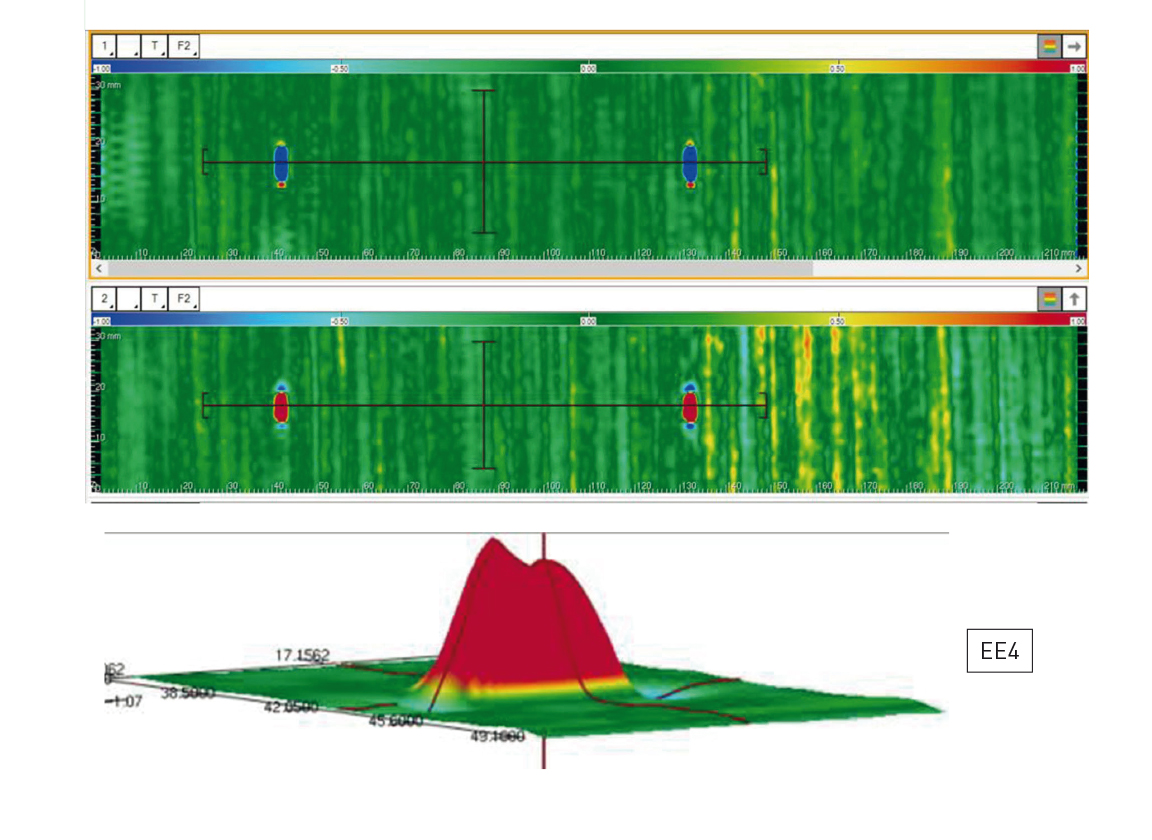

Crack height sizing by Eddy Current Array testing

When they carry out surface tests on their parts, professionals of the sheet metal working sector need to obtain the most comprehensive and reliable dimensional data so that they can use it, on the one hand, to confirm the need for repairs and determine the conditions said repairs, as applicable, and, on the other hand, to use it as input data for fracture mechanics calculations. As the testing methods used until today, i.e. penetrant testing or magnetic particle testing, are not exhaustive due to their limits regarding crack sizing (length and height), the sheet metal working and piping commission (CHTT) selected two processes which could be used as alternatives: active infrared thermography (already studied) and Eddy Current Array (ECA), addressed in this document. The assessment (9Q421) presented in this document was performed on specimens made of stainless-steel grade 316L; their fatigue-induced flaws were subjected to sizing tests using the ECA testing method, then sections were cut across the flaws in order to measure their actual heights and, finally, the results obtained during the tests were compared with the results of the height measurements performed further to cutting.

Author : Jean-Yves Rolland, Cetim

Updated 08/27/2021