Mecatheque

Results of collective works

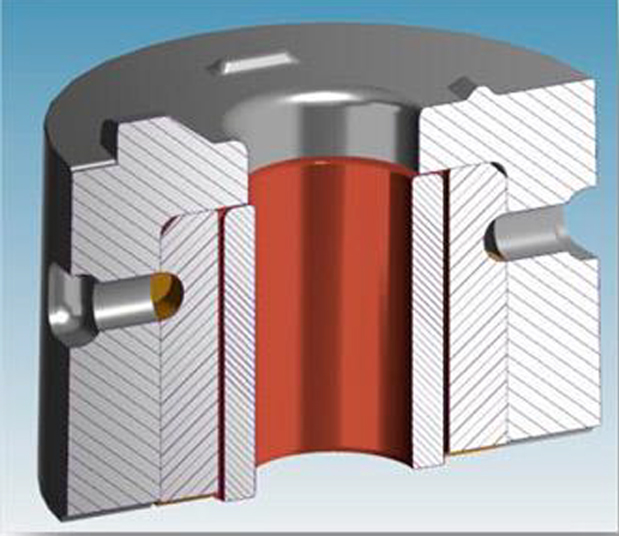

Additive manufacturing of hot-forging tooling

The production cost of a forged part is heavily dependent on the cost of the tooling used, which represents 10–20% on average according to previous Cetim studies. Increased throughput as well as industry demand for longer-lasting hot-forging tooling mean that is it vital to increase and control tooling lifetime. Factors that influence lifetime, such as the thermal conditions and temperature increases, degrade their mechanical properties. Although solutions for cooling tools do exist, they have their limitations. Adding a thermal control function by integrating channels is one response to this requirement – this can increase tooling lifetime and throughput, improve the dimensional quality of parts, limit the number of rejects at the start of series and make it possible to forge parts with forging limits due to their geometric features or the material. The confidentiality associated with the design of forging tooling unfortunately prevented completion of the study programme initially planned. Only one of the manufacturers contacted responded to our request, providing a case based on stamping tooling comprising two tools: a lower die and an upper die. The study (S2042) of this tooling led to the conclusion that this technology can provide the expected results.

Author : Pierre KRUMPIPE, Cetim

Updated 03/03/2021