Design - Simulation - Tests

Headlines

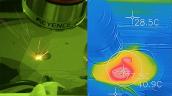

Video: “I am Sure” project monitors metal additive manufacturing

detection of incipient defects reveals its results in a new video.

The “I am Sure” project has proven that it is possible to perform real-time in-process monitoring of metal additive manufactured parts. The project partners developed a system that can be used to detect the formation of defects on parts produced with the Selective Laser Melting (SLM) and Directed Energy Deposition (DED) processes. Learn all about the project in the video “Additive Manufacturing - innovative solutions for real time defects detection” on Youtube.

From preparation through to characterisation

Sponsored by the machine manufacturer BeAM (acquired by Addup), the project brought together players from all sectors, namely Airbus, Naval Group, Thales, CEA List, Cetim LNE, VLM, Polyshape and the French rapid prototyping association. As part of the project, Cetim was tasked with developing a detection system, which it implemented on “model” parts and subsequently used X-ray tomography after manufacturing to qualify the results.

This video takes a look at the key steps in this experiment - preparation, manufacturing, in situ control using acoustic emission technology and fatigue characterisation work to qualify the harmfulness of the detected defects - for each of the studied processes (DED and SLM).

Watch the video “Additive Manufacturing, - innovative solutions for real time defects detection” on the Cetim France Youtube channel.

Other informations

VibSEA – Controlling high frequency vibrations of aircraft engines

Headlines

The European project provides a response to the need of engine manufacturers to extend the fiel...

Video: Cetim takes up the challenge of metal additive manufacturing

Headlines

In a new video, Philippe Lubineau, Chief Research Officer at Cetim, talks about this key techno...

Results of studies

ASME Boiler and Pressure Vessel - Code Week Meetings - November 2019 - Version Anglaise

Dimensioning of form tapping – Phase 3

Tests of synthetic ropes –Lf200 curve

Material fatigue - Factors influencing the fatigue strength of metal of metal materials

JTC10 – Material efficiency – Summary of standards

References

Aluminium foams released into the stratosphere

( CNES)Remaining useful life: the turbine remains in operation

( Suez EVNA)CFD simulation to optimise performance

( TotalEnergies Fluids)Comprehensive support for validation plans

( Sonceboz)Support at every stage of development

( Purple Alternative Surface)Presentation

With product modelling and simulation potential solutions can be virtually optimized before they are really implemented. We tend to set up a more efficient design by taking fatigue life into account and optimizing safety factors within a fiabilist approach. The main goal is to achieve much shorter development deadlines. Major improvements are experienced in the field of simulation dealing with more and more complex and multi-physical phenomena.

This technological focus includes projects relating to : fiabilist design of products, functional requirement and performance qualification checking, analysis methods based on customer needs, design of clean and silent products, simulation of product behavior and operation.