Back > Control and Measurement

Expertise in non-destructive testing

Non-destructive testing

NDT, as a preventive measure, according to regulations or subsequent to a failure

Are you looking to automate/robotise the testing of your production, inspect your equipment or have an external opinion about a metallic, composite or multi-material product? Do you need:

- A solution to automate or robotise the “in line” testing on one or more stations of a production line?

- A solution to detect or characterise defects?

- An expert investigation or a confidential second opinion from a neutral organisation?

- To have standard tests carried out by certified technicians?

- To comply with standards and codes or update your compliance?

Cetim can provide you with support over all or part of a comprehensive value chain ranging from the determination of functional and organic specifications to an “industrial” testing solution

- Based on an analysis of your requirements, recommendations regarding the most appropriate testing method, from amongst a panel of conventional or innovative techniques including ultrasonic imaging, TOFD, ultrasonic phased array testing, active infrared thermography and guided waves.

- The performance of feasibility tests using numerical simulation or models, design of testing equipment, probes, supports, optimisation of testing parameters via simulation or on standard parts

- The preparation of specifications for the automated testing system, identification of suppliers, monitoring of performance, acceptance, support and training for your staff

- The design and optimisation of tests using simulation software

- The performance of tests by COFREND-certified technicians (CIFM and COSAC) in methods such as penetrant testing, magnetic particle testing, ultrasonic testing, Eddy current testing, acoustic emission testing and X-ray testing.

- Methods specifically tailored to your context, as several testing methods can be used during the same service

- Deliverables: an automated/robotised testing system, a detailed and explicit report with potential proposals for corrective actions (failure analysis, redesign, etc.)

- Cetim is an independent result-oriented organisation

Non-destructive testing simulation from design

Incorporate testing from the design phase of your product

100% inspection of spindle fitting

( Komori-Chambon)Industrial autoclaves: Testing without dismantling

( Aeroform)Quick quality control of moulded valves

( Total)Assessing integrity and repairability

( Stir)Combining expertise and reactivity

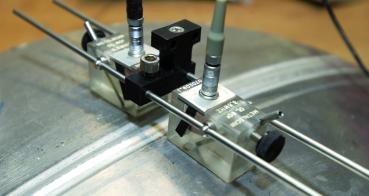

( Continental Automotive France)Catenary Systems: Inspections on the line

( SNCF) ()NDT expertise in hydropower

( Hydrostadium)Accumulators are worthwhile for service

( Interforge)Expert investigation of gates for a dam in Morocco

( Tractebel)Two penstocks get wiretapped

( EDF Tignes Malgovert)Checking leak tightness by acoustic emission

( Entrepose Contracting)Active infrared thermography is an obvious solution

( Otecmi)Defects identified using flash lamps

( Duqueine group)Tailored failure analysis training

( NTN Transmissions Europe)Detecting burns by noise

( Lufkin France)Diagnosis of a giant drain valve

( Tractebel Engineering)Phased array for testing ring gears

( Ferry-Capitain)Winning expertise

( Team Banque populaire )Vibration analysis in support of the beauty sector

( L'Oréal) ()Acoustic emissions: monitoring of composite rings

( CNIM)Control of materials, products and equipments

Cetim offers you its expertise in non-destructive testing and measurements, from simple part inspection to process instrumentation including the management of measuring instrument tools, in order to meet each requirement, whether related to products or processes.

Your NDT (Non-Destructive Testing) operators can also obtain COFREND certification in one of the 2 Cetim examination centres (Senlis and Nantes, France).