Equipment

Headlines

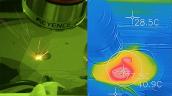

Video: “I am Sure” project monitors metal additive manufacturing

detection of incipient defects reveals its results in a new video.

The “I am Sure” project has proven that it is possible to perform real-time in-process monitoring of metal additive manufactured parts. The project partners developed a system that can be used to detect the formation of defects on parts produced with the Selective Laser Melting (SLM) and Directed Energy Deposition (DED) processes. Learn all about the project in the video “Additive Manufacturing - innovative solutions for real time defects detection” on Youtube.

From preparation through to characterisation

Sponsored by the machine manufacturer BeAM (acquired by Addup), the project brought together players from all sectors, namely Airbus, Naval Group, Thales, CEA List, Cetim LNE, VLM, Polyshape and the French rapid prototyping association. As part of the project, Cetim was tasked with developing a detection system, which it implemented on “model” parts and subsequently used X-ray tomography after manufacturing to qualify the results.

This video takes a look at the key steps in this experiment - preparation, manufacturing, in situ control using acoustic emission technology and fatigue characterisation work to qualify the harmfulness of the detected defects - for each of the studied processes (DED and SLM).

Watch the video “Additive Manufacturing, - innovative solutions for real time defects detection” on the Cetim France Youtube channel.

Other informations

A whole week of testing for future training technologies

Headlines

From 22 to 26 March 2021, new learning tools were assessed under real conditions in the Hauts-d...

Video: Cetim takes up the challenge of metal additive manufacturing

Headlines

In a new video, Philippe Lubineau, Chief Research Officer at Cetim, talks about this key techno...

Scientific publications

- Galling detection by acoustic emission according to ASTMG98

- Thermomechanichal study of high speed rolling element bearing: a simplified approach

- Robust Active Control of The Milling Process Vibrations in a fixed reference frame

- 3D numerical simulation of drilling residual stresses

- Influence of the lubrication conditions on surface integrity in drilling

References

Failure analysis to determine the root cause of a leak

( ECM Technologies)Optimised, high-performance and silent gears

( Pellenc)A "smarter" workshop

( Anthoine Bernard et Fils)Dynamic sealing capacity of the seal of a mining mill

( Ferry-Capitain)Fault analyses completed in double quick time

( Locapal)Results of studies

ASME Boiler and Pressure Vessel - Code Week Meetings - November 2019 - Version Anglaise

Tests of synthetic ropes –Lf200 curve

Material fatigue - Factors influencing the fatigue strength of metal of metal materials

JTC10 – Material efficiency – Summary of standards

Guide to Fatigue Design of Components and Structures

Presentation

Within a very competitive international context and in a restructuring period, Cetim has developped for this sector special solutions for research, innovation and support. Mechatronics, new materials, innovative manufacturing processes... all of them are assets to develop the high-value products required by the market.