Metal Processing

Headlines

Video – The QSP process gains further headway

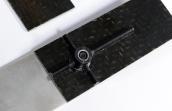

The Quilted Stratum Process for thermoforming of thermoplastic composites is now ready for the manufacturing of a composite bumper beam and has gained new possibilities for direct intramould assembly of metallic inserts.

The Quilted Stratum Process (QSP) developed by Cetim has broadened its range of applications. In fact, the thermoforming pilot line created by Cetim and its partners Loiretech, P.E.I. and Compose, has been configured to manufacture a vehicle composite bumper beam, as an alternative to conventional solutions. This line includes the cutting of patches from thermoplastic composite plates or tapes, the assembly of “patched” preforms, rapid heating, and a thermoforming press used to obtain net shape parts. This application can be seen on video on our website and on the Cetim France YouTube channel.

Intramould inserts

The QSP process also has more added value on account of the developments performed between Cetim and the specialist of industrial fasteners Böllhoff Otalu. The partners have worked in two stages. Firstly they equipped the QSP intramould drilled holes Rivkle SFC inserts made by the German company. Then, they integrated and directly overmoulded an Imtec CF metal insert into the stamping mode. As an added benefit, they provide increased mechanical strength. “With respect to a conventional solution assembled with a composite drilled by machining, these solutions integrated to the QSP increase performance respectively by 30 to 75% with regard to tearing, 60 to 75% as regards tensile-shear strength, in addition to the energy absorption gain”, stated Emmanuelle Berlire, Innovation project manager at Böllhoff. This innovation received an “Innovation Award” at Experience Composites 2016. The next step will be to develop a specific product designed for applications of structural fasteners for composite parts.

Read the full “Böllhoff Otalu – New assemblies for composites” reference sheet on our website, in the “References” section.

Other informations

A whole week of testing for future training technologies

Headlines

From 22 to 26 March 2021, new learning tools were assessed under real conditions in the Hauts-d...

Video: Cetim takes up the challenge of metal additive manufacturing

Headlines

In a new video, Philippe Lubineau, Chief Research Officer at Cetim, talks about this key techno...

Video: “I am Sure” project monitors metal additive manufacturing

Headlines

detection of incipient defects reveals its results in a new video. The “I am Su...

Scientific publications

- Galling detection by acoustic emission according to ASTMG98

- Thermomechanichal study of high speed rolling element bearing: a simplified approach

- Robust Active Control of The Milling Process Vibrations in a fixed reference frame

- 3D numerical simulation of drilling residual stresses

- Influence of the lubrication conditions on surface integrity in drilling

References

Fault analyses completed in double quick time

( Locapal)Test protocols tailored to each implant

( Newclip Technics)Acceptance of a key Vulcain 2.1 engine component

( ArianeGroup)Assistance in automated polishing

( Chapuis Armes)Better characterize the powders to better use them

( Chpolansky)Results of studies

ASME Boiler and Pressure Vessel - Code Week Meetings - November 2019 - Version Anglaise

Dimensioning of form tapping – Phase 3

Feasibility study of the multi-directional forging technology - PHASE 2

Material fatigue - Factors influencing the fatigue strength of metal of metal materials

Additive manufacturing of hot-forging tooling

Presentation

Deeply touched by crisis, this industry can rely on the various skills offered by Cetim to reinforce its competitiveness.

Innovation, product ranges redesign, process or organizational expertise... Cetim suggests you alternative solutions and takes part in supporting this essential-to-the-industrial-production market.