Headlines

Back > Headlines

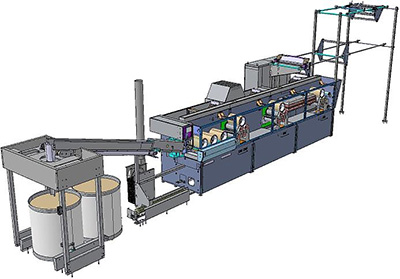

N. Schlumberger is modelling the energy efficiency of its machines

N. Schlumberger performed a full energy audit of a stretch breaker. The simulation made it possible to better understand the influence of some settings and to identify areas of improvement.

As a sign of our times, the energy efficiency of machinery is now a selection criterion for industrial decision-makers. N. Schlumberger, a manufacturer of machines for the textile, environment and energy sectors, is fully aware of this requirement. Therefore, the company commissioned Cetim to analyse its new textile stretch breaker.

“Customers want to know the energy cost per metric ton produced, explains Marc Domas, manager of electrical studies at N. Schlumberger. We therefore commissioned Cetim to perform a study in order to more accurately determine the capacities involved and examine the areas for improvement.”

In the scope of the Capme’Up programme, initiated as part of the “Investissements d’avenir” (“investments of the future”) project, the modelling of the entire power transmission chain was then undertaken and measurements (torque, force, temperature and electrical power) were recorded on an instrumented machine.

The model was used to analyse the influence of some settings such as band speed, on the operation of the stretch breaker. It also helped to identify the power and loss paths through the transmission components.

Consult the full “Reference” sheet on the Cetim.fr Website, “Prestations” (services) section, “References” space.

- Cegelec CEM selects AFT/Fathom to optimise its nuclear cooling systems Optimising the sizing and design of nuclear equipment cooling systems requires appropriate high...

- The European project EASI-Stress is launched ! Residual stress is easy with the EASI-Stress project! The general objective of the European pro...

- An International index for ISO 128. The ISO 128 series of standards has been given a makeover. Indeed, some parts of the standard a...

- A 1D simulation tool for Getinge Lancer. With the help of a calculation tool requiring no expert knowledge in hydraulics, developed by C...

- Duplication of a Renault wear test bench. At the request of Renault, Cetim has duplicated a test bench for the characterisation of fricti...