Headlines

Back > Headlines

High-precision 3D scanning now at Cetim

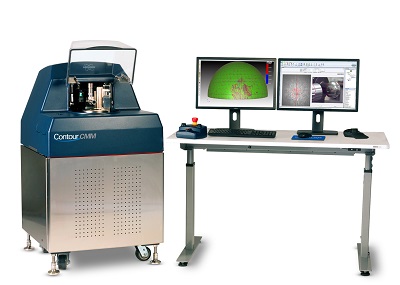

Bruker, a German company, has decided to entrust one of its two Contour CMM machines to Cetim. This machine is able to associate shape and surface topology measurement on very small-sized components, thereby paving the way for high-precision 3D scanning.

A world premiere at Cetim Senlis: in September 2016, the centre has acquired one of the two Contour CMM optical measuring machines made by Bruker! If you want to see the other one, you'll have to travel to… the USA.

A unique machine

The Contour CMM machine associates shape measurement (micron accuracy) and surface topology measurement (accuracy: a few nanometres) by white light interferometry on a single equipment item. It can thus perform high-precision 3D scans of components within a work area contained in a 100-mm diameter sphere. This makes it possible to detect and accurately locate any surface anomaly on a component. The measurement result, a cloud of several millions of points, can thus be used for metrological purposes or to build a 3D template of the component compatible with CAD or digital simulation software. Possible applications include studying very local wear on prostheses or optical components, or characterising manufacturing defects at nanometre scale on specific machined components.

One year of measurements

The purpose of the agreement signed between Bruker and Cetim is to validate the precision and performance of the machine. For this purpose, for one year, measurements will be carried out on various industrial components, on the site located in Picardy (France). All sectors using small-sized and high-precision components are concerned: aviation, automobile, medicine, precision mechanics, etc. Cetim is also involved in the improvement of the German company's programming and data processing software.

With this equipment item, the centre now boasts a comprehensive 3D metrology offer, ranging from the measuring drone for very large or inaccessible parts to high-precision 3D scanning on very small parts, including 3D measurement with high-precision multipliers, with the newly-acquired Werth Video-Check HA measuring machine.

- Cegelec CEM selects AFT/Fathom to optimise its nuclear cooling systems Optimising the sizing and design of nuclear equipment cooling systems requires appropriate high...

- The European project EASI-Stress is launched ! Residual stress is easy with the EASI-Stress project! The general objective of the European pro...

- An International index for ISO 128. The ISO 128 series of standards has been given a makeover. Indeed, some parts of the standard a...

- A 1D simulation tool for Getinge Lancer. With the help of a calculation tool requiring no expert knowledge in hydraulics, developed by C...

- Duplication of a Renault wear test bench. At the request of Renault, Cetim has duplicated a test bench for the characterisation of fricti...