Headlines

Back > Headlines

Cleaning: a selection of clean technologies for the industrial sector

Three industrialists are giving explanations about new generations of organic solvents, supercritical CO 2 and dry steam degreasing.

Ecotec, Cetim’s great R&D programme implemented in collaboration with CEA, Cirimat and Ademe with funding from the European Union, has provided good results. Three new cleaning technologies are currently in the limelight.

“We have created a patented mixture of organic solvents which includes selected substances that are harmless for people and the environment”, says Jean-Philippe Testa, CEO of Arcane Industries. Today, we want these eco-friendly solvents to be widely used in industrial washing machines”. In the long run, the purpose is to design, with Cetim, a solvent suitable for one or several cleaning machines under development with industrialists.

Research on dry steam cleaning has resulted in the joint development of a closed-circuit steam cleaning machine. With this approach, Cetim is only paid by Royalties upon completion of the marketing phase. “In collaboration with Cetim, we defined the specifications for this machine which will clean components stored in a cleaning basket with water and steam without using any additives”, explains Philippe Ridel, CEO of the eponymous company. Today, this machine has reached the end of its development phase.

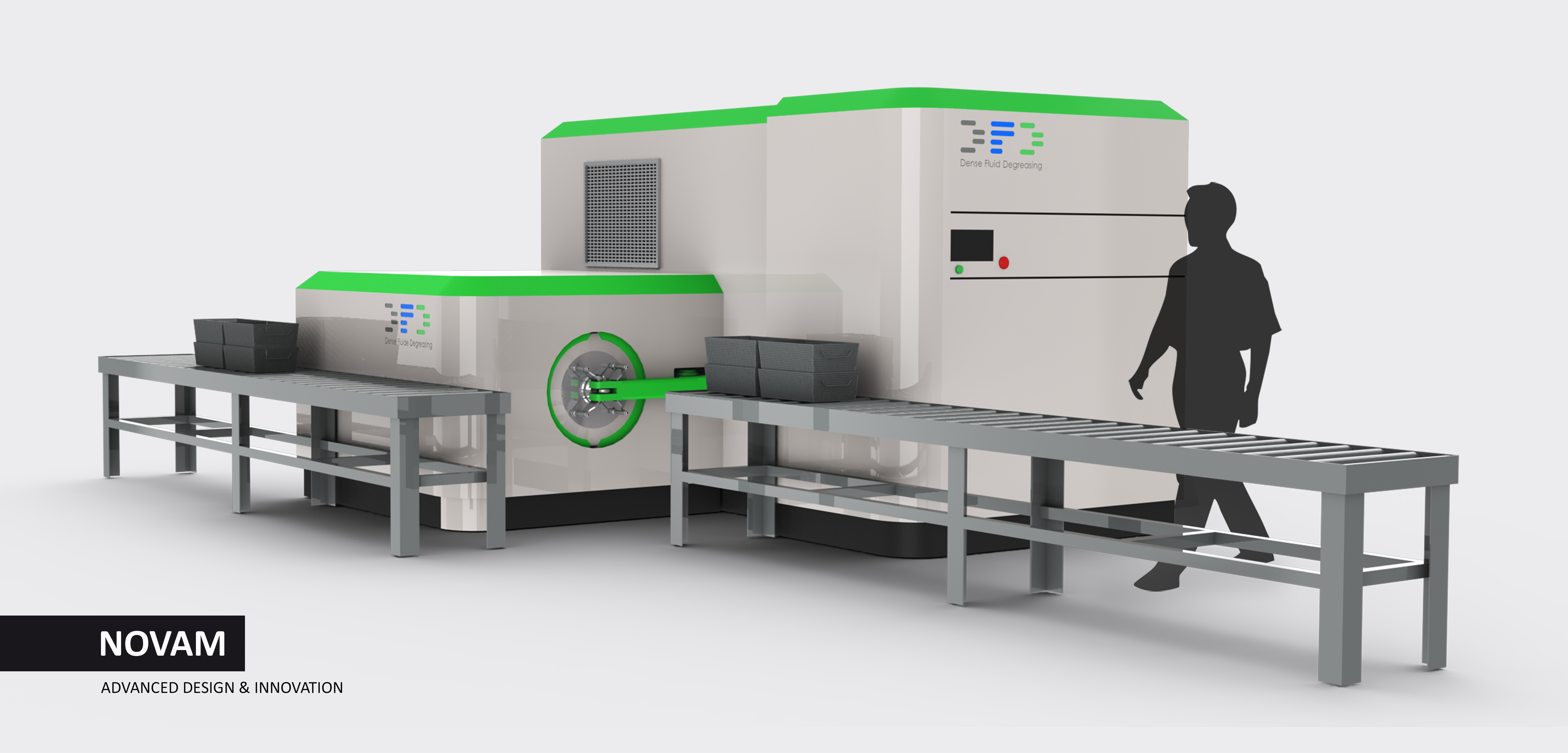

As regards DFD, the new machine which works with supercritical CO 2 (SC CO 2) has been developed jointly with Cetim. The advantages of gas and liquid are combined in this fully dry process. “In this machine, the machining particles and separated by gravity at the bottom of the tank while other polluting substances (cutting oils, surface treatment fluids, etc.) are cleaned off by the SC CO 2“, explains Sylvie Berruel, Business Developer for DFD. The CO 2 is totally purified upon completion of the process, then it is recycled at liquid state within the machine. In addition to a positive environmental balance, operating cost is reduced by more than 25 %! “The ecodesign strategy implemented with Cetim also helped us obtain this result”, adds Sylvie Berruel.

Find out more information in Cetim news No. 227 dated October 2014.

- Cegelec CEM selects AFT/Fathom to optimise its nuclear cooling systems Optimising the sizing and design of nuclear equipment cooling systems requires appropriate high...

- The European project EASI-Stress is launched ! Residual stress is easy with the EASI-Stress project! The general objective of the European pro...

- An International index for ISO 128. The ISO 128 series of standards has been given a makeover. Indeed, some parts of the standard a...

- A 1D simulation tool for Getinge Lancer. With the help of a calculation tool requiring no expert knowledge in hydraulics, developed by C...

- Duplication of a Renault wear test bench. At the request of Renault, Cetim has duplicated a test bench for the characterisation of fricti...